The first time I made this 'chain' I used 9.5mm rings, which I think I prefer, but as I couldn't remember this fact due to a faulty memory issue and a perverse tendency to refuse to write notes, I used a 10.5mm mandrel to make these particular links. You might be relieved to hear that this was O.K. No catastrophe occurred and, in fact, it reinforced my belief that anything goes as long as you make it seem as though you meant to do it that way in the first place.

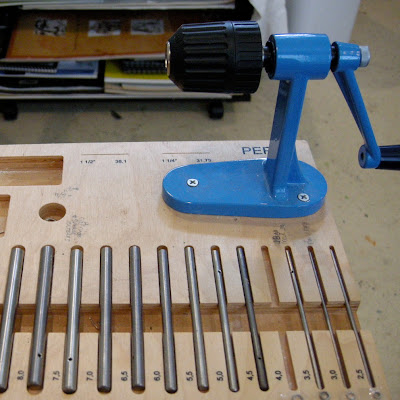

This is my jump ring maker. Love it. Except I've given up using the saw blade and ring holder vise that comes with it. I've tried many times but just can't get the hang of it. I've also tried the tape and regular jewelers saw to cut the rings, but that is annoying to me as well and (I think) time consuming. So now I just snip the rings with my good wire snippers as and when I need them. I turn the blade after each snip so that the join in the rings will meet flat for soldering. For me this is a quick and effective way to make jump rings. You don't need the ring maker to make jump rings. Just some good mandrels. This looks handy, and it's only $15. Not sure how sturdy it is though. Most of my tools come from either Rio Grande or Otto Frei. I get my silver from Rio Grande. I bought some from a different site once and it was filled with so much copper that as soon as I sanded it it was pink. Don't chance it unless you really trust the site you're buying from.

I used 20 gauge sterling silver wire to make these rings.

(Note: although I love the look of the 9.5mm ring size in this 'chain', the chain doesn't move as freely as it did when I made it using the 10.5 mm rings. As I wasn't making a full length chain I was happy with the results. If I were making a full length chain, to hold a pendant, etc., I would rather the links had more movement and therefore would perhaps use a smaller gauge of wire, or the larger mandrel size.

As it is, who can afford to make a full length chain with the price of silver today...)

Moving on,

I then soldered the links together.

I bought some of this solder a while back. It is a paste mix, in a syringe, and is supposed to come out of the syringe in the amount you need with the exact amount of solder and flux mixed together.

However, I was a bit disappointed when I first got it as it was really, really expensive and, on top of that, I couldn't plunge the plunger thing into the syringe as apparently I'm not The Hulk. It was just way too hard. But, I have come to find that for small solders, such as jump rings, etc., it is great, I just have to dig the paste out with a small paint brush instead of syringing it. When it's gone I might even buy some more, although I see that Rio Grande doesn't have the silver solder in the syringe form right now - somebody must have mentioned the Hulk problem.

(Note, at this point, N made me a cup of tea in my favourite mug. Oh, and see that nail file next to it, I use that to file the end of my ear wires. No extra charge for that tip.)

Now, after soldering, you could pickle the links and maybe even sand off the excess solder. (As I'm not the expert solderer, I probably should have followed my own advice here.)

I didn't.

Instead I went straight to the next step because I'm a, let's get to it, I can't wait around forever, kind of person. Soooo,

take your round nose pliers,

and stretch the links.

(F.Y.I. Don't freak out but this really tests how good your solders are ...)

Now you are going to squeeze the middle of the elongated link together,

This should all be easy as the heat from soldering will have softened the wire. Unless your solders aren't strong enough and then you're going to have to start all over again ... sorry ...

(You can see that my solders aren't exactly perfect, but I refuse to let that get me down. They are waaaaay better than they were, and, we all have to begin somewhere ...)

Now, bend the loop.

When they are all bent you put two of them (or more) together, as shown.

This looks like some kind of chinese puzzle but keep at it as it is possible. You can do it. (Excuse the little fabric hair thing that seems to have attached itself to my link.)

This is when I clean mine.

You can:

1. Put the finished chain or individual links in pickle.

2. Make up the entire chain and tumble it.

Or, you can do as I do (probably not always the best advice...) which is to,

3. Hold the links in your round nose pliers and sand them with one of those painting prep sanding blocks.

Maybe this is why I'll never become a famous jeweler ...

Saying that, I use these as links, not as a chain (hence the title of this blog) - which makes them way easier to handle when cleaning. I've not made a whole chain yet as I am satisfied right now to learn what I can when I can and to know that everything will come in time. (Did I also mention the cost of sterling right now?)

I hope you, too, will enjoy your creativity and realize that you 'can' ... because, if I can, you certainly can :)

When I finally get around to cleaning these they will be fantabulous :)

Stay positive ...

Disclaimer: I am just a somebody muddling through. This is the way I do things. I am a wing it, try it, do it wrong, try again, sort of person. I do not maintain that I know what I am doing, only that I am trying to do it. Please feel free to enjoy my discoveries but follow your own research for professional advice and to perfect your skills. Above all, enjoy. Life is short.

What a great tutorial :-) I love your disclaimers and sense of humor! And such pretty pieces in your shop, btw

ReplyDeleteThanks Jennifer. I thought perhaps it was a bit wordy - maybe confusing, but as that seems to be how I live my life, I figured I'd just do it :)

ReplyDeleteLove the title of your blog btw

ReplyDeleteI like your way of doing, it is my way too, if it works for me - that's okay, peace to you.

ReplyDeleteI have that same paste solder...it is the best! I keep it warm by putting it in my bra and I can press it out of the syringe just fine.

ReplyDeleteHahaha Vera who says bra's are useless😀

ReplyDeleteYou have a wonderful way of explaining things! Thank you for your wonderful words of wisdom!

ReplyDeleteКрасиво!

ReplyDeleteHola, me gustaría saber si la medida de 10.5 mm. corresponde al diámetro de la cadena o al largo del alambre que usaste para hacer la cadena. Gracias

ReplyDeleteI really found your commentary and explanations very easy to understand. As I learn it’s reassuring to know what some of the ‘bumps in the road’ can be as well.

ReplyDelete